| unit weight: | |

|---|---|

| Availability: | |

| Quantity: | |

NJEFG

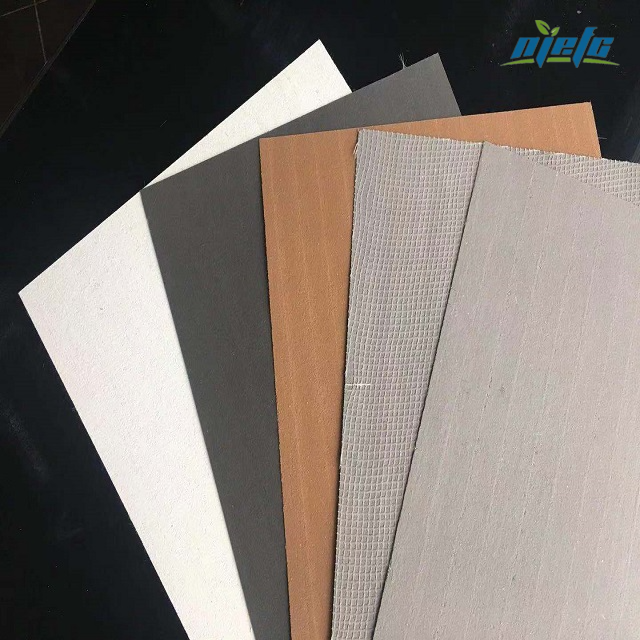

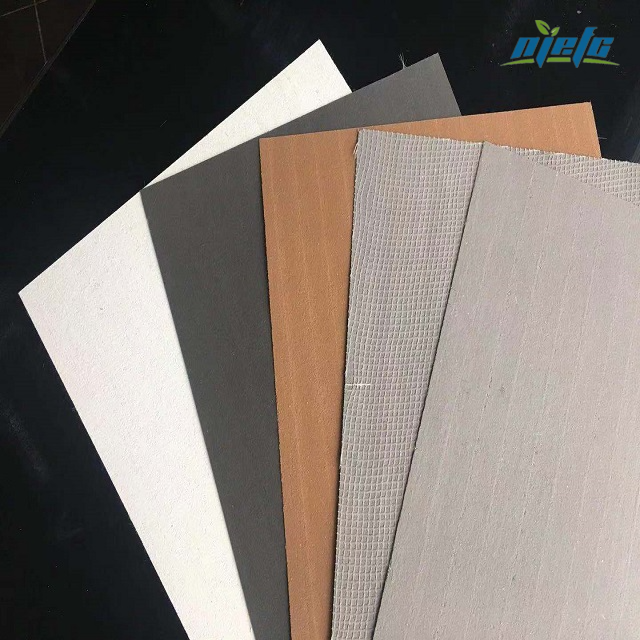

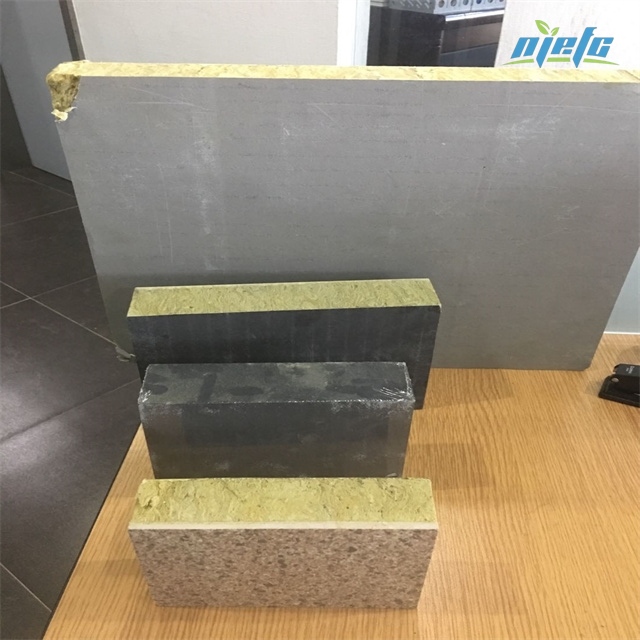

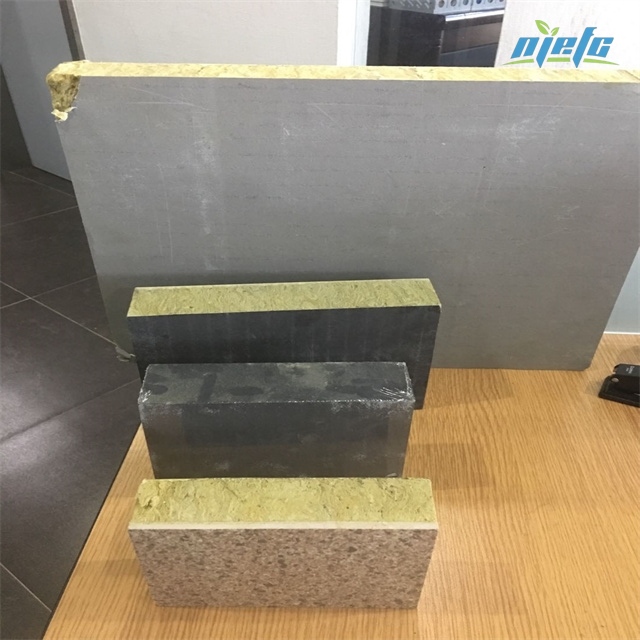

The coated fiberglass mat is a functional material to be covered on the surface of external wall insulation board such as mineral wool board and polyurethane board, which use fiberglass mat as a base material, being coated with the compound of stone powder, cement, binder and other functional fillers. After covering with the coated fiberglass mat, the break strength of the insulation board is obviously improved, the coated fiberglass actually become a shielder of the insulation board, increased the waterproofing futures of the insulation board. Since the coated mat is covered with the cement and stone powder, which make the insulation board can be attached on the wall with cement directly, simplified the mounting process.

The coated fiberglass mat is a functional material to be covered on the surface of external wall insulation board such as mineral wool board and polyurethane board, which use fiberglass mat as a base material, being coated with the compound of stone powder, cement, binder and other functional fillers. After covering with the coated fiberglass mat, the break strength of the insulation board is obviously improved, the coated fiberglass actually become a shielder of the insulation board, increased the waterproofing futures of the insulation board. Since the coated mat is covered with the cement and stone powder, which make the insulation board can be attached on the wall with cement directly, simplified the mounting process.

Coated fiberglass mat are widely used in below fields,

1. Surface covering of mineral board

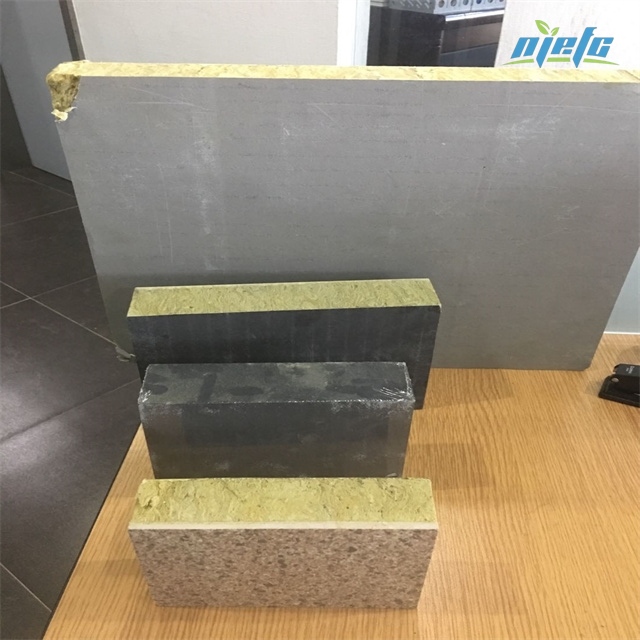

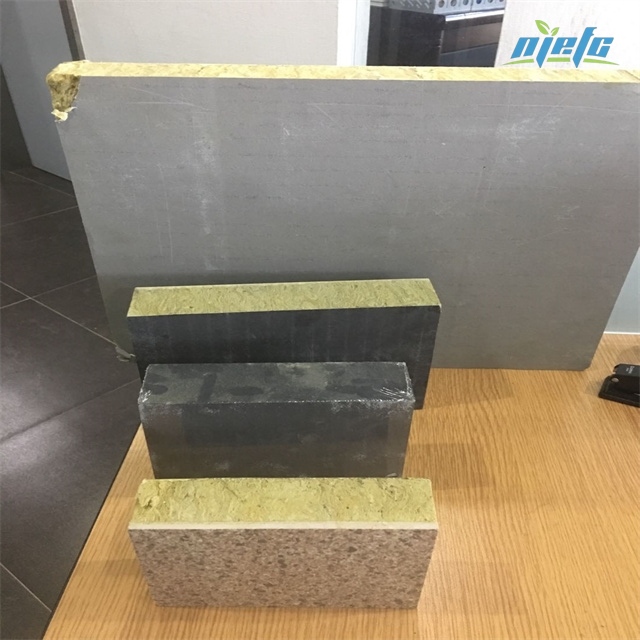

CCM-320 is excellent material for the surface covering of mineral board. This coated fiberglass mat is not fully impregnated with the compound. Usually impregnate 4/5 of the fiberglass mat on thickness, leaving 1/5 of the fiberglass mat on thickness without coating. Then use the fiberglass layer of the coated mat to attach to the mineral board, the lamination will be excellent.

2. Surface covering of polyurethane board

CCM-400 is designed for the surface covering of polyurethane board. For this application the fiberglass mat is fully impregnated with the compound. It have thicker coating layer, And minimized the porosity of the coating layer. This structure efficiently avoided the leakage of polyurethane foam during the polyurethane board producing.

WHY CHOOSE CCF MAT LAMINATED INSULATION BOARD?

1. Disadvantages of traditional insulation board

Lower tensile strength of the mineral wool itself

Low interfacial strength with cement mortar

Quickly decreasing of tensile strength after long-time working

Irritating to human body

Higher water absorbtion: after absorbing water, the physical and mechanical properties of rock wool board falling greatly, much influenced by freezing and thawing damage.

2. Advantage of CCF Mat laminated insulation board

A-Grade fireproofing

Perfect waterproof performance

Excellent mechanical property

Excellent adhesion between the CCF mat laminated insulation board and the wall

Regularized size, flatness, high strength of the board, good impact resistance

Enriched size choice, excellent mechanical property and workability

No need waterproof treatment, double-layer fiberglass or steel wire mesh reiforcement.

Continuous producing line, high efficiency, good quality controllability

Traditional plastering process, technology is mature, high efficiency

Safety application of the CCF Mat laminated insulation board

Operation cost effective

Perfect features of temperature viriation resistance, flexibility and climatic ageing resistance.

Health friendly - the most important point

Coated fiberglass mat are widely used in below fields,

1. Surface covering of mineral board

CCM-320 is excellent material for the surface covering of mineral board. This coated fiberglass mat is not fully impregnated with the compound. Usually impregnate 4/5 of the fiberglass mat on thickness, leaving 1/5 of the fiberglass mat on thickness without coating. Then use the fiberglass layer of the coated mat to attach to the mineral board, the lamination will be excellent.

2. Surface covering of polyurethane board

CCM-400 is designed for the surface covering of polyurethane board. For this application the fiberglass mat is fully impregnated with the compound. It have thicker coating layer, And minimized the porosity of the coating layer. This structure efficiently avoided the leakage of polyurethane foam during the polyurethane board producing.

WHY CHOOSE CCF MAT LAMINATED INSULATION BOARD?

1. Disadvantages of traditional insulation board

Lower tensile strength of the mineral wool itself

Low interfacial strength with cement mortar

Quickly decreasing of tensile strength after long-time working

Irritating to human body

Higher water absorbtion: after absorbing water, the physical and mechanical properties of rock wool board falling greatly, much influenced by freezing and thawing damage.

2. Advantage of CCF Mat laminated insulation board

A-Grade fireproofing

Perfect waterproof performance

Excellent mechanical property

Excellent adhesion between the CCF mat laminated insulation board and the wall

Regularized size, flatness, high strength of the board, good impact resistance

Enriched size choice, excellent mechanical property and workability

No need waterproof treatment, double-layer fiberglass or steel wire mesh reiforcement.

Continuous producing line, high efficiency, good quality controllability

Traditional plastering process, technology is mature, high efficiency

Safety application of the CCF Mat laminated insulation board

Operation cost effective

Perfect features of temperature viriation resistance, flexibility and climatic ageing resistance.

Health friendly - the most important point

Product code | Unit Weight (g/m2) | Pull strength (MPA) | MD/CD Tensile Strength (N/5cm) | Roll width (mm) | Roll length (m) | Roll diameter (mm) |

CCM-320 | 320 | >0.10 | >200/100 | ≤1260 | 900 | ≤750 |

CCM-400 | 400 | >0.15 | >250/200 | ≤1260 | 700 | ≤750 |

Testing Basis | GB/T 9914.3-2011 | |||||

【Storage】

This product should be stored in a dry, ventilated and rainproof place, with temperatures from 5℃to 35℃ and humidity between 35% and 65%. It is recommended to be kept in intact package when not used to avoid damp.

【Customization】

Cement coated fiberglass mat in above table are the standard types Nanjing EFG CO., LTD is delivering to customers, if customer wants specific unit weight, tensile strength, roll width and roll length, Nanjing EFG CO., LTD can produce per customer’s requirement, offer tailored service to customers from different countries.

【Packaging】

1. Roll packaging: PE plastic film

2. Pallet packaging: Pallets should NOT be stacked in more than 2 layers. Pallet is free of fumigation, fumigation certificate is available

【Loading】Standard export loading

【Markets】Nanjing EFG CO., LTD. has delivered cement coated fiberglass mat to USA, EU, Middle East, North Africa, South Africa, Asian customers with ensured quality and rich experience for export deliveiry. Nanjing EFG CO., LTD welcomes the cooperation from all of the world.

【Delivery】cement coated fiberglass mat will be loaded into container in factory, then be delivered to the sea port, finally be shipped to Customer’s port by MSK, MSC, CMA, COSCO, YANGMING, APL, etc.

【Payment】LC, T/T, CAD, PAYPAL, WESTERN UNION, ETC.

【After sales service】Nanjing EFG CO., LTD tracks cargo of every shipment till customer uses the cement coated fiberglass mat, and offer any help for customer’s demand in any time.

【Technical support】If customer meets any problem about technic, Nanjing EFG CO., LTD will supply relative knowledge to help customer find the best solution, and can send technician to customer’s factory for guiding.

Product code | Unit Weight (g/m2) | Pull strength (MPA) | MD/CD Tensile Strength (N/5cm) | Roll width (mm) | Roll length (m) | Roll diameter (mm) |

CCM-320 | 320 | >0.10 | >200/100 | ≤1260 | 900 | ≤750 |

CCM-400 | 400 | >0.15 | >250/200 | ≤1260 | 700 | ≤750 |

Testing Basis | GB/T 9914.3-2011 | |||||

【Storage】

This product should be stored in a dry, ventilated and rainproof place, with temperatures from 5℃to 35℃ and humidity between 35% and 65%. It is recommended to be kept in intact package when not used to avoid damp.

【Customization】

Cement coated fiberglass mat in above table are the standard types Nanjing EFG CO., LTD is delivering to customers, if customer wants specific unit weight, tensile strength, roll width and roll length, Nanjing EFG CO., LTD can produce per customer’s requirement, offer tailored service to customers from different countries.

【Packaging】

1. Roll packaging: PE plastic film

2. Pallet packaging: Pallets should NOT be stacked in more than 2 layers. Pallet is free of fumigation, fumigation certificate is available

【Loading】Standard export loading

【Markets】Nanjing EFG CO., LTD. has delivered cement coated fiberglass mat to USA, EU, Middle East, North Africa, South Africa, Asian customers with ensured quality and rich experience for export deliveiry. Nanjing EFG CO., LTD welcomes the cooperation from all of the world.

【Delivery】cement coated fiberglass mat will be loaded into container in factory, then be delivered to the sea port, finally be shipped to Customer’s port by MSK, MSC, CMA, COSCO, YANGMING, APL, etc.

【Payment】LC, T/T, CAD, PAYPAL, WESTERN UNION, ETC.

【After sales service】Nanjing EFG CO., LTD tracks cargo of every shipment till customer uses the cement coated fiberglass mat, and offer any help for customer’s demand in any time.

【Technical support】If customer meets any problem about technic, Nanjing EFG CO., LTD will supply relative knowledge to help customer find the best solution, and can send technician to customer’s factory for guiding.

Tel: +86 25 52270147

Fax: +86 25 58321442 / 52255211

Mob: +86 18851651909

Whatsapp: 0086 18851651909

Email: fiberglass@njefg.com

Website: www.china-fiberglass.com